Automatic Four Head Edible Oil Liquid Diesel Dish Disinfecting Honey Laundry Detergent Bottling Filling Machinery Industry Equipment

4 Nozzles Viscous Dishwasher Liquid Filling Machine Bottle with Capping Labeling production line can automatically arran

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | TAFM-4PM-ZX |

| Dosing Device | Capacity Cup |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Capping Machine Working Speed | 20-60 Bottles / Minute (Depending on Bottle and Ca |

| Filling Accuracy | 1% ( Based on Water) |

| Size of Air Compressor Connector | Od 8mm |

| Power Supply | 220V-50Hz/ 110V-60Hz |

| Capping Machine Working Pressure | 0.4-0.6 MPa |

| Filling Head | 1heads/ 2heads |

| Filling Speed | 20-60 Bottles/Min |

| Product Name | Monoblock Automatic Filling Production Line |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Ply-Wooden Case |

| Specification | L250*W110*H175cm. |

| Trademark | TOPCN |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 10sets/Month |

Product Description

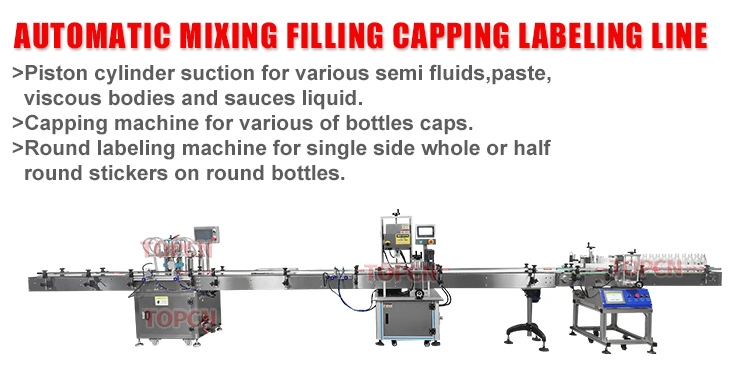

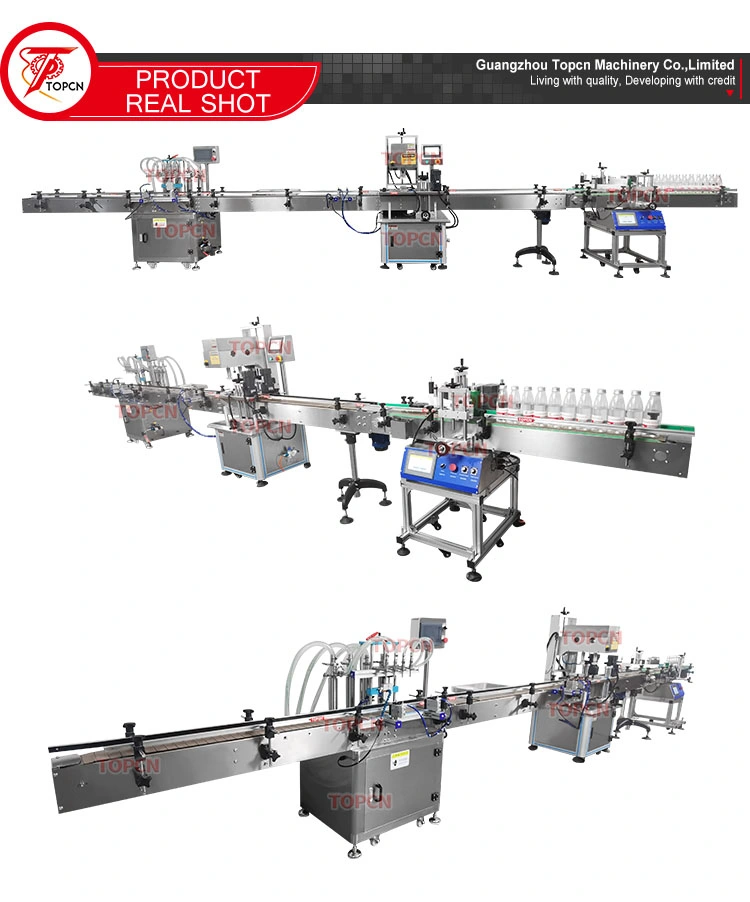

4 Nozzles Viscous Dishwasher Liquid Filling Machine Bottle with Capping Labeling production line can automatically arrange bottles,filling can capping and labeling for semi fluids, viscous bodies and sauces liquid,it helps to save production process and improve working efficiency.We can offer custom service for different kinds of materials,make these machines can match your material better. It is widely used in food,beverage,cosmetics and pharmaceutical industries.

Working progress:

1:Feeding bottle 2:Filling 3: press capping 4:Screw Capping 5:Induction foil sealing 6:Labeling 7:Bottle collecting

| Automatic Filling Machine | |||

| Model | TAFM-4PMZX | TAFM-6PMZX | TAFM-8PMZX |

| Voltage | 110/220V 50-60HZ 800W | ||

| Filling Range | 10-120ml/25-250m/50-500ml/100-1000ml/500-3000ml/500-5000ml | ||

| Working Speed | 20-40bottles/min | 30-45bottles/min | 35-50bottles/min |

| Filling Accuracy | ≤±1% | ||

| Air Pressure | 0.5-0.7MPa | ||

| Size Of Air Compressor Connector | φ10mm | ||

| Conveyor length | 2050mm(standard ) / 3050mm(wider version) | ||

| Conveyor material | Plastic(standard) / stainless steel(custom version) | ||

| Machine weight | 260kg | 300kg | 500kg |

| Machine size | 2050x860x1460mm | 3200x860x1460mm | 2500x1100x1600mm |

| Automatic Capping Machine | |

| Bottle Height | 50-350mm |

| Bottle Caps Diameter | 20-60mm |

| Working Speed | 0-40 bottles/minute (depending on bottle and caps) |

| Working Voltage | AC220V/110V 50-60HZ 300W |

| Working Pressure | 0.4-0.6 MPa |

| Capping Torsion | 4-9kgf/cm |

| Packing Size | 2100*470*1240mm |

| Automatic Round Labeling Machine | |

| Voltage | AC 110V or AC 220V 50/60Hz 100w |

| Speed | 20-100pcs/min |

| Bottle Height | 25mm-380mm |

| Lable size | Length:10-350mm; Width:20-100mm |

| Precision | ±1mm(depends on bottle shape) |

| Label roll | φ76.2-φ350mm |

| Objects | Bottles, jars, cans, boxes, cartons, juice bottles, beer wine bottles, shampoo detergent bottles, etc. |

| N.W. | 120Kg.(G.W. with wooden case 180KG) |

| Dimension | 1220×850×800mm |

| Function | This machine can stick labels on various objects, Bottles, jars, cans, boxes, cartons, beer bottles, wine bottles, juice bottles,shampoo detergent bottles, hardware, etc. |

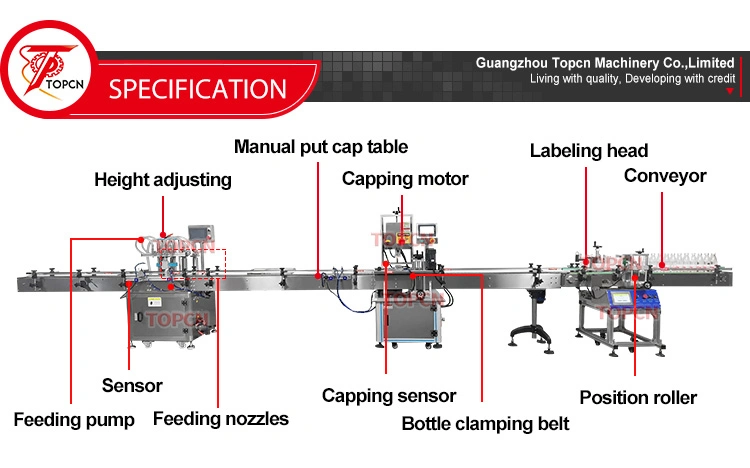

Filling nozzles

viscous liquid filling machine with multiple nozzle,each filling nozzle can be controlled separately.It is with anti-dripping design,this ensure the cleanliness during production,improve production quality.This machine can be customize into 2/4/8 filling nozzle according to your needs,if you need this please contact

Accept customized cap feeding station

liquid filling machine bottle with bottle cap feeder which can feed lids before capping bottle.This one needs to be customized according to cap size.

Motor protect cover.

Capping head with steel protect cover, ensure safety productionLabeling Roller

Three labeling wheel makes bottles rotating and labeling, ensure that all label stick on same position of bottle and no bubbles. It is also suitable for AB sticker labeling.Date coding

It can priting MFD(manufacture date), EXD(expiry date), BATCH((batch lot) Can priting 3 lines Thermal transfer ribbon printer optionalCapping roller

There is no limitation of cap shapes,dishwasher liquid filling capping machine is suitable for different kinds of bottle caps like spray bottle caps,shampoo bottle caps etc.

FAQ

Q1: Are you a machine manufacturer or trading company?A1: We are a reliable machine manufacturer that could give u the best service. And our machine can be customized by the client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?A2: Every machine is tested by our factory and other clients before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in the warranty year.

Q3: How can I install this machine when it arrives?A3: We will send the engineers overseas to help the client installing, commissioning, and training.

Q4: Could I choose the language on touch screen?A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider. 2) After choosing the suitable type of machine, then tell me the filling capacity you need for the machine. 3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine? A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke, how to solve the problem?A7: Yes, we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke, how to solve the problem?A8: First of all, please take the pic or make a video to show the problem parts. After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q9: Do you have manual or operation video for us to know more about the machine? A9: Yes, we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke, how to solve the problem?A10: Yes, we will send you the manual and operation video after you ask for us.

Q11: If there's some spare parts that broke, how to solve the problem?A11: First of all, please take the pic or make a video to show the problem parts. After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Related Products

-

![Bridge Saw 5 Axis CNC Marble 3D Stone Carving Stone Cutting Machine]()

Bridge Saw 5 Axis CNC Marble 3D Stone Carving Stone Cutting Machine

-

![Automatic Four Head Edible Oil Liquid Diesel Dish Disinfecting Honey Laundry Detergent Bottling Filling Machinery Industry Equipment]()

Automatic Four Head Edible Oil Liquid Diesel Dish Disinfecting Honey Laundry Detergent Bottling Filling Machinery Industry Equipment

-

![Automatic Paper Carton Erecting Forming Machine For Hamburger Paper Box Fast Food Box Tray Forming Machine]()

Automatic Paper Carton Erecting Forming Machine For Hamburger Paper Box Fast Food Box Tray Forming Machine

-

![Multi]()

Multi