Cake Box Pre Fold Crash Lock Bottom Box Folder Gluer Die Cutting Machine Used Plate Cardboard Box Making Machine Folder Gluer From China

SH-650 Automatic Folder Gluer Specification Folding specificatio Function and Profile 1.Equipped with full color touch s

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SH-650 |

| Power | 17kw/380V |

| Air Tank Capacity | 60L |

| Paste | Solute Property |

| Folding Wany | Belt Folding |

| Optional Box Type | Straight Line, Crash Lock Bottom, Double Sides |

| Suitable Paper | 200-650GSM Cardboad, E/ F/ N Corrugated Board |

| Speed | Max.300m/Min |

| Max Width of Folding Box | 650mm |

| Feeding Way | Continuous Automatic Paper Feeding |

| Transport Package | Retort Stand and Vacuum Packaging |

| Specification | 14100mm*1350mm*1400mm, 4500 kg |

| Trademark | Sinhosun |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 1000 Pieces/Year |

Product Description

SH-650 Automatic Folder Gluer

Specification

| Model | SH-650 |

| Suitable paper | 200-650 g / m² card paper cardboard, E,F,N Corrugated board. |

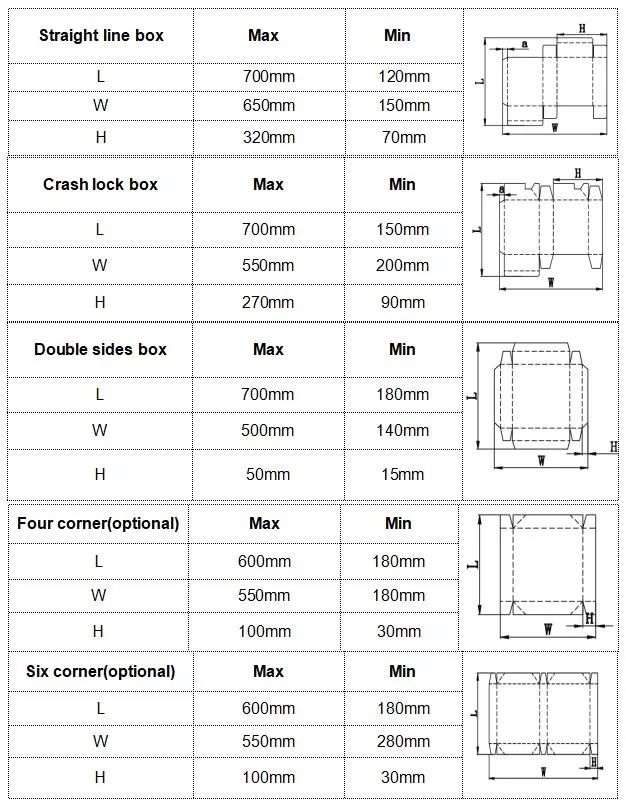

| Box type | Standard: Straight line, crash-lock bottom, double sides box,optional for 4/6 corner box,CD box |

| Feeding way | Continuous automatic paper feeding. |

| Glue type | Solute style |

| Max. speed | 300m/min |

| Power | 10.5KW, AC220V/380V |

| Weight | 4.5T |

| Dimension | 14100mm*1350mm*1400mm(L*W*H) |

| Inching speed | 40m/min |

| Compressed air | 6 bar |

| Air compressor capacity | 10m³ |

Folding specificatio

Function and Profile

1.Equipped with full color touch screen monitor system, the main machine, and conveyor can control the speed automatically and trace the parameter setting system synchronously.2. Equipped with mobile adjustment for each plate , elaborate screw rod design, easy and fast operation by one people , high efficiency.3. High efficiency speed conversion and powerful electric motor, equipped with strong belt for power transmission, high efficiency, low voice, easy maintenance and economic benefit. 4. Standard pre-folding , double sides and lock bottom folding , elaborate design, easy and fast operation. 5.The upper and lower glue tank equipped with unique design for special box.(Optional unit: hot&cold automatic gluing system) 6.The press folding and conveyor equipped with adjustive pressure design for special products and a set of special soft belt for average pressure to ensure the perfect quality. 7. Photo-electric count, viable and quantitative count, equipped with kick board identification equipment.

Partial Mechanism Function Description

Feeder

- Paper feeding independent motor frequency control.

- Main motor speed ratio linkage, pasting box process to keep the box spacing stable.

Pre-folding section

- Plates transportation (left 180º, right 135º), especially for the boxes' need to run on automatic packing flow line.

- Can be upgraded for 4/6 corner box, servo control back system.

- The bottom hook is equipped with a high-speed edge grinding machine and equipped with air suction and dust removal.

- Unique design for upper and lower glue tank and matching products (optional for cold and hot glue automatic spraying system).

- Lengthening this folding part to meet the long box folding requirements, such as LED box.

- The upper and lower belt was driven by motor for smooth box transportation.

- The upper and lower carriers separately, which is conducive to adjust the length separately.

- paper receiving belt and coordinate with guide roller, stable and not easy to cause the damage of the box.

- The speed of the delivery pressure part can be adjusted automatically or manually according to the speed of the host machine.

- The pneumatic adjustment of pressure,effective to facilitate the box paste.

- Depending on the length of the box ,the output pressure part can move back and forth.

- Photo-electricity counting, quantity counting is available, pneumatic kicker for mark is used. Human-computer interface, which can be controlled scientifically, and easy operation.

- The two sets of servo axis ensure that the anti-hook folding movement is accurate, and the setting can be easily completed by the touch screen.

- Intelligent servo motor drive control electronic anti-hook system.

Basic Mechanism Description

1.Feeder:(1)Independent motor frequency control(2)Japan NITTA feeder belt (one set/ 7 pieces)(3)Vibration system (one set)2.Pre-folding section:(1)Left 1st indentation line 180° pre-folding, right 3rd indentation pre-folding.

(2)Special plastic steel bearing pedestal.3.Bottom hook section:(1)Special plastic steel bearing pedestal.

(2)Bottom lock accessory (one set)

4. Down glue tank:

(1)Down glue tank (left & right)

(2)Stable at high speed, without glue throwing and leakage.

(3)Glue wheel knurling treatment (10mm).

5. Final folding section:

(1)Final folding electric shift plate.

(2)Special plastic steel bearing pedestal.

6. Compression section:

(1)Photoelectric quantitative count.

(2)Pneumatic mechanical kicker counter.

(3)Japan NITTA transfer folding belt (one set/4 pieces)

7. Conveyor:

(1)Frequency control, linking with main machine.

(2)4.6 m long, one point pressure adjustment mechanism, with wide pressure range,

even pressure of each part.8.Electrical system: (1)Low voltage apparatus: AC relays, button, intermediate relay, fuse all are from French.

(2)Converter is from Taiwan Delta.

(3)PLC and touch screen of human machine interface are from Taiwan Delta.

9. Others:

(1)Buyer autonomous the above air compressor.

Service

Sinhosun give our heartfelt thanks for your choosing of our products, service is our core. Our "lifetime worry-free service" covering the whole life cycle of equipment from service efficiency, service speed, maintenance cost and quality standard, and realize a customer-oriented value chain.

Pre-sale

According to your requirements and the providing box sample specification , our sale person will provide professional technical consultation services, and develop relevant solutions, and providing the performance and characteristics of products, etc.. In the early stage, sale person will communicate with you, ensure the models and specification of the equipment. Also we can custom machine for your special requirements, providing you a satisfactory reasonable production line.

After-sales

1. Establish one machine and one record management system

Our company implements the whole-process tracking management system from the factory to the useful lifespan of the products. Archiving management including the product name, specification model, factory number, date and user information , also including product acceptance registration, product assembly, the factory state, installation, customer situation, training, warranty and maintenance period of technology, quality records, and product transfer track records, etc, to ensure the quality security work of each sold equipment .

2. One-year warranty and lifetime service

From the day of equipment acceptance, we will provide free parts replacement services to you during warrant period, the freight of parts will be borne by buyer.After one-year warranty, if your equipment failure, we will provide technical assistance, and provide you with paid maintenance services, including fault maintenance, replacement of the original factory parts.