Automatic Hot Heating Corrugated Paper Dry Food Carton Thermal Film Laminator (GKFM

Overview Product Description Detailed Photos GKFM-YT semi-automatic thermal film laminating machine is a multi-functiona

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | GKFM-520YT/920YT/1100YT |

| Plastic Film Mulching Modes | Water-Base |

| Total Power | 16kw |

| Power Supply | 380V/50Hz |

| Dimension | 4000*1340*1650mm/4000*1740*1650mm/4000*1940*1650mm |

| Machine Weight | 2/2.2/2.6t |

| Suitable Paper Specifications | 105-500G/M |

| Biggest Effect of The Width | 520/920/1100mm |

| Model | Gkfm-520yt/920yt/1100yt |

| Pressure of Work | 10-16MPa |

| Largest Machine Output Speed | 40m/Min |

| Max Diameter Volume The Original Film | 500mm |

| Transport Package | Wooden Case |

| Trademark | GK |

| Origin | China |

| Production Capacity | 20sets/Month |

Product Description

Product Description

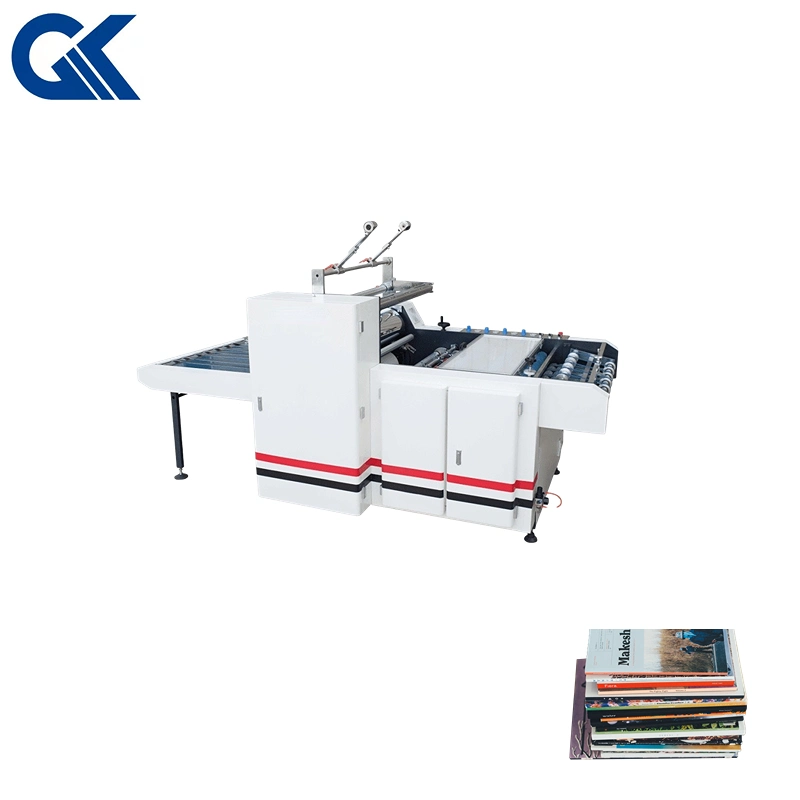

GKFM-YT semi-automatic thermal film laminating machine is a multi-functional laminator which is newly developed upon customers feedback and market need for pre-coating film and glueless film.It can laminate paper without gluing by pre-coating film and glueless film in certain temperature and pressure.This machine advoids environmental pollution and toxic residuum from traditional laminating technology , reduces energy-loss and saves production costs.

It's widely applicable to laminate teaching materials,books, periodicals, product samples, manuals, charts, maps,the outer package of audio and video products and other publications.The laminated products will be water-proof,durable, 3D for clear picture and good effect.

The machine is equipped with frequency convener to adjust working speed and heating roller with hydraulic system for lamination.It has features of high speed ,low noise and stable running ,which a good choice for large and middle model film laminating enterprise.

Configuration and Construction:

Man-machine interface system: color touch screen make operation easy and convenient. Input the paper size ,distance and speed, etc can realize the whole machine automatic operation. Operator can check the status of machine on touch screen. Feeding table adopts air-sucking paper feeding and equipped with front guide device to make paper feeding, folding stable and neat.Film cutting knife cuts film width to make it meet paper size. Film perforated knife can perforate film edge to realize automatically separating. Separating system: disc flying knife film-cutting device with precision and high speed.Anti-curve device can avoid paper curvature due to shrinkage of film

Model | HM-520YT | HM-920YT | HM-1100YT |

Biggest effect of the width | 520mm | 920mm | 1100mm |

Pressure of work | 10-16Mpa | 10-16Mpa | 10-16Mpa |

Largest machine output speed | 40m/min | 40m/min | 40m/min |

Largest diameter volume the original film | 500mm | 500mm | 500mm |

Power supply | 380V/50HZ | 380V/50HZ | 380V/50HZ |

Total power | 16kw | 16kw | 16kw |

Machine is suitable for paper specifications | 105-500g/m | 105-500g/m | 105-500g/m |

Dimensions In | 4000×1340×1650mm | 4000×1740×1650mm | 4000×1940×1650mm |

Machine weight | 2T | 2.2T | 2.6T |

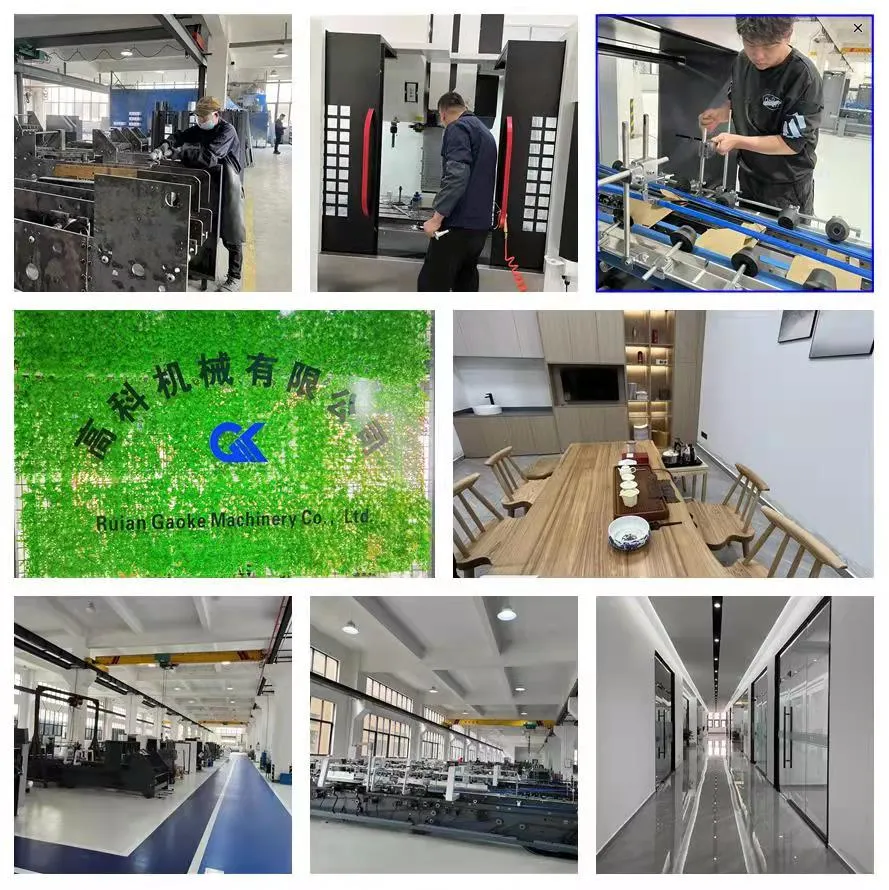

COMPANY INTRODUCTION:

Ruian Gaoke Machinery Co., Ltd, was established in 2006. As a professional manufacturer, we not only do manufacturing, but also researching, marketing and offering after sales service. We supply quality equipments, effective and convenient solutions for cardboard box and corrugated box folding industry, printing and packaging industry.

OFFICE

FAQ

1Q:Are you manufacturer? A:Yes, we are folding gluing and window patching machine manufacturer with 10-year experience and profession.2. Where is your company located? How can I visit there?

A:Our new factory address: No.18, Wansheng, Road, Wanquan Ind. Zone, Pingyang, Wenzhou, Zhejiang, China.The nearest transportation center is Wenzhou Longwan airport or Ruian train station. 3.What's your advantages ?_machines designed to quickly adjustable _machines have good paper adaptability _first-rate attractive and reasonable price_rich experience and profession.-double paper servo control --Customers all over the world --Certificate: CE certificate --Fast reply:Our team will reply you soon. -After sale service:We have a after sale department, service for your problems and dealing with spare parts.4

Q:What is the production time while placing order? A:About 30 daysOur faith:1) Society's Avail First 2) Client's Avail First 3) Employee's Avail First 4) Enterprise's Avail Second

If you have any inquiry, please don't hesitate to contact us. We will reply to youat the first time as we can.

Related Products

-

![Qzx1370d7 54X57 Inch Hydraulic Program Control Paper Cutting Machine Paper Cutter]()

Qzx1370d7 54X57 Inch Hydraulic Program Control Paper Cutting Machine Paper Cutter

-

![Automated High Quality Efficient Guillotine Program Control Hydraulic Heavy Duty Paper Cutter]()

Automated High Quality Efficient Guillotine Program Control Hydraulic Heavy Duty Paper Cutter

-

![Boway 4908 Electric Paper Cutter Program Control Paper Cutter]()

Boway 4908 Electric Paper Cutter Program Control Paper Cutter

-

![165m/Min Heavy Duty High Speed Automatic Cardboard Corrugated Paper Flute Laminator]()

165m/Min Heavy Duty High Speed Automatic Cardboard Corrugated Paper Flute Laminator